BACK TO HOME

Tapping & Tubing

Strategies for maintaining high sap yields with 3/16 tubing

Tim Wilmot | August 3, 2018

Sap yields from 3/16” tubing on a slope compared to yields from 5/16” tubing are generally very good in the first year, particularly with gravity tubing, but also in many cases when using a pump—as described in two recent articles in The Maple News.

However, yields reported by many users begin to decline, usually by a moderate amount, after the first year. This is particularly true if the tubing is not cleaned at the end of the season.

In part, this is due to the nature of the tubing, which holds onto sap much more tightly than 5/16” tubing, generating natural vacuum in this manner; in some cases it also holds onto sap containing bacteria and yeasts. [ MORE ]

3/16ths guru Tim Wilmot: Using 3/16th tubing with a pump

Timothy Wilmot Researcher, Dominion & Grimm Inc. Retired, University of Vermont Extension Maple Specialist | Jan. 25, 2018

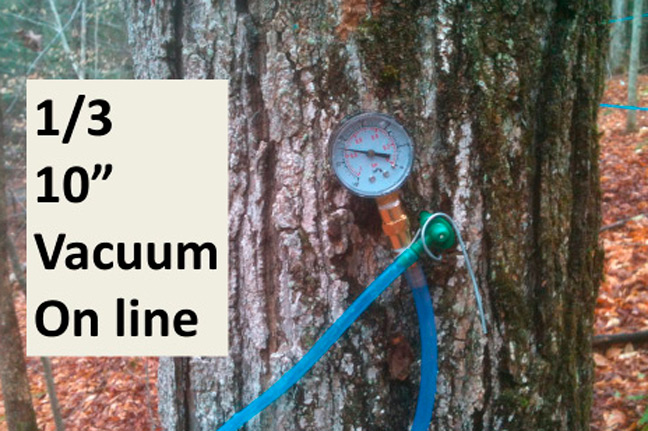

In addition to the advantages that 3/16” tubing provides in creating natural (gravity) vacuum on a slope, there is also an advantage that small diameter tubing can provide in some pumped systems. As is true with an all gravity system, the goal is to maximize vacuum at each taphole. Research has shown that an increase in vacuum at the taphole is accompanied by a steady increase in sap production—the relationship is about 5% more sap for every additional inch of mercury. In many pumped systems, because of friction loss and the capabilities of the pump itself, the vacuum at the taphole is less, sometimes much less, than the maximum that is possible at that elevation.

On a slope, the vacuum that can develop in 3/16” lines can increase what is achieved in the mainline by the pump, and this increase may boost production. The vacuum in the small lines is developed by the weight of the sap, while the vacuum in the mainline comes from the steady removal of air by the pump; together they form what I call a hybrid. This type of system is somewhat newer than the all gravity 3/16” system, and its design, for example the optimum number of taps per line, is less straightforward.

This article summarizes the research that I have conducted on 3/16” hybrid systems; unless otherwise noted, all of the results reported here are my own.

[ MORE ]

3/16ths guru Tim Wilmot. The gravity of it all.

Tim Wilmot, University of Vermont Ext. Maple Specialist (retired) Researcher for Dominion and Grimm Inc. | Jan. 13, 2018

The use of 3/16” tubing for sap collection began as a series of experiments that I conducted while working at the University of Vermont Proctor Maple Research Center.

The goal was to devise a gravity sap collection method that would improve production for sugarmakers with small operations who typically collected much less sap than producers using vacuum pumps.

Over the past 8 years I have continued to conduct research with this tubing in an effort to learn more about its potential uses and possible shortcomings, both for gravity and pumped sap collection.

[ MORE ]

Sugaring in December

PETER GREGG | Oct. 1, 2017

Some call it defying Mother Nature, others would call it taking advantage of her, but the fall tappers are at it again.

“I only planned on having enough sap to boil on the stove,” said Cody Armstrong, one of the few brave souls who tapped trees this fall. “I thought it would be cool.” [ MORE ]

The Take Down Master

Peter Gregg | April 2017

It’s hard to believe Tony Van Glad is still smiling.

Van Glad, a 6,300-tap producer in the Catskills region of New York, is one of the few sugarmakers who put up and then take down their entire pipeline system every season. [ MORE ]

Sugarmakers invent gadget for easy droplines

Caleb Schrock & Jeremy Swartzentruber | December 2016

We have done tubing installations and made droplines so we know how time consuming, strenuous and monotonous making drop-lines can be.

We knew there had to be better [ MORE ]

Man vs. Squirrel

Peter Gregg |

The arch enemy of sugarmakers is the squirrel.

More than maybe any other force of nature—a bad season, a bad wind, fallen branches—it’s the hordes of gray and red squirrels that cause the most costly damage in the woods, chewing up tubing, fittings and spouts. [ MORE ]

Results in from 2016 3/16” tubing research

Stephen Childs, NYS Maple Specialist |

The 2016 maple sap season offered an interesting look at the effects of 3/16” tubing on vacuum without significant elevation drop and some comparisons of 3/16” tubing with and without the addition of mechanical vacuum. [ MORE ]