BACK TO HOME

Tapping & Tubing

Tapping tips from the experts, as new season begins

Peter Gregg | January 12, 2026

EDEN, Vt.—As sugarmakers prepare to return to the woods in the coming weeks, proper tapping should be on their minds.

Ideal tapping depth has generally been determined by the experts to be two inches.

“Going deeper than two inches means you are making more injury to the tree with no additional gain in sap,” according to UVM Proctor Center director Dr. Timothy Rademacher during a recent seminar.

If on high vacuum, one tap per tree is fine, he says. If on gravity, a second tap will only give an additional 20 percent gain. And a third tap will give zero additional sap, he said.

Sugarmaking legend Glenn Goodrich has been stressing the importance of taphole precision.

“Getting a true round hole in the trees is essential,” Goodrich told producers during a recent seminar.

[ MORE ]

Vermont sugarmaker offers expert tubing tips

Peter Gregg | February 4, 2025

WESTMINSTER WEST, Vt.—Veteran sugarmaker Dan Crocker has been making syrup more than fifty years and over the past several seasons, he has achieved a 7lbs per tap average.

It didn’t always used to be that way.

The old benchmark for big-time Vermont sugarmakers—Crocker has 22,000 taps in southern Vermont—was an average of 5 pounds per tap, and he would hit that mark consistently.

But then he did the math, and found that for each one pound increase, he’d be putting an extra $40,000 in his pocket.

“The math is easy,” he told a group at the Lake Erie Maple Expo last fall. “That adds up fast.”

So he targeted 7lbs and has high hopes for 2025.

“And this season I’m going to be pushing 8 pounds,” he said. [ MORE ]

Sugarmakers prefer tapping frozen trees

Peter Gregg | January 15, 2025

SYRACUSE, N.Y.—A normal winter.

That’s how most sugarmakers are describing January of 2025 so far, with bitter cold temperatures and lots of snow all across the Maple Belt.

Meanwhile, the enthusiasm for January tapping seems to have diminished for some.

Last year at this time, many sugarmakers were making syrup already.

In fact, sugarmakers in traditionally cold areas like Wisconsin and Minnesota, even ones on gravity, we’re making January syrup last season.

This year not so much.

But that doesn’t mean producers should abandon plans to tap early in freezing cold temperatures. In fact, for many, it’s preferred. [ MORE ]

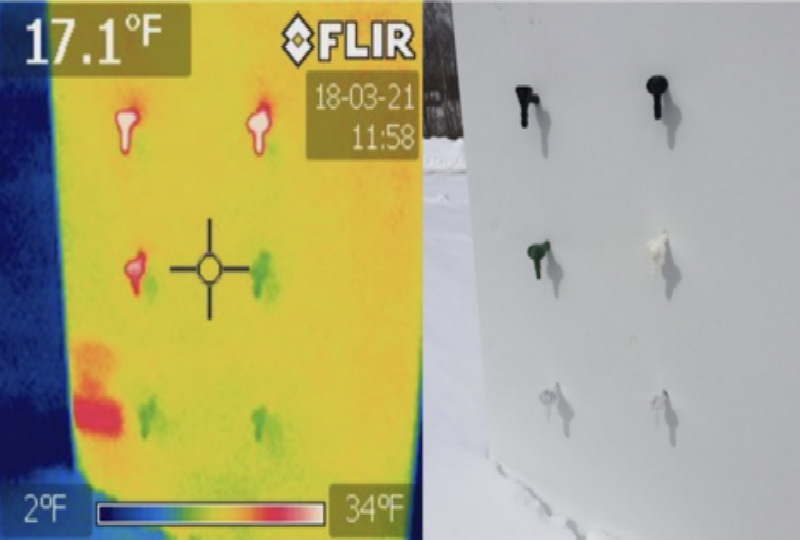

Does high vacuum 'create' leaks? Expert explains.

Michael Ruff, Becker Pumps Corp. | July 23, 2024

CUYAHOGA FALLS, Ohio—In recent years, the use of deep vacuum systems for maple extraction has sparked debate, with some concerns that these systems cause micro leaks in tree taps.

However, it’s crucial to distinguish fact from fiction.

Deep vacuum doesn’t create leaks; it merely exposes existing ones.

Before delving into the deep vacuum debate, let’s revisit the process of maple syrup extraction:

■ During the sugaring season, small holes are drilled into maple tree trunks to create taps. These taps allow sap to flow out for collection and sub- sequent processing.

■ Traditionally, gravity has been the primary force drawing sap from the trees into collection containers.

■ Technological advancements have intro- duced vacuum systems that significantly enhance sap extraction efficiency.

[ MORE ]

Producers encouraged to find their 20-day 'money window'

Peter Gregg | January 16, 2024

THOMASTON, Conn.—When to tap?

That’s always the sugarmaker dilemma every season but this year it seems more pronounced than others.

Wild weather and big temperature swings across the Maple Belt has had producers excited one minute and hesitant the next.

Contributing to the matter are Facebook posts from big producers who are forced to tap early because of the size of their operations, and capture early sap runs in December and January.

When to tap was the big topic of conversation this weekend at the annual meeting of the Maple Syrup Producers Association of Connecticut.

“I’m not sure when I’m going to start this season,” said Mat Wilkinson of 800-tap Wilkinson Maple Farm in Columbia, Conn.

Offering some perspective was the keynote speaker at the meeting Bradley Gillilan of Gillilan Family Maple in Fletcher, Vt. who is a tubing installer and consultant to sugarmakers across the nation.

[ MORE ]

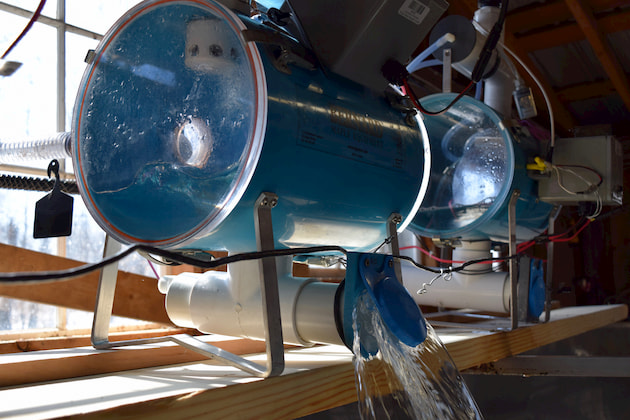

Vermont sugarmaker offers tips on tubing cleaning

Peter Gregg | November 3, 2023

SOUTH WOODSTOCK, Vt.—One of the biggest debates in maple is over the best method for cleaning tubing, or even bothering to clean it at all.

At 1,200-tap Top Acres Farm in South Woodstock, Vt. sugarmaker Mary McCuaig has developed what she says is a tried and true method.

"We use a weaker chlorine solution and begin cleaning as soon as the season ends," she told The Maple News.

"This method has allowed us to avoid replacing spouts and droplines annually and still keep yields high," McCuaig said.

"We average over half gallon of syrup per tap, and our sap is clean, starting with the first sap run."

McCuaig has posted three YouTube videos explaining her method under her YouTube channel- marymccuaig3249. [ MORE ]

Proctor reports on 2023 season barb-spout results

By Timothy D. Perkins & Wade T. Bosley | May 18, 2023

UNDERHILL, Vt.—The outermost rings of wood in maple trees have the highest sap flow rates and have sweeter sap than the wood found deeper in the tree.

In addition, during the early part of each season there are several periods when thawing is too brief and shallow to allow sap to be collected.

This is because typical maple spouts have elongated barrels that are inserted well into the wood to anchor them in place. While this design feature of spouts reduces the tendency of sap to dislodge during deep freeze periods, it doesn’t permit sap collection during brief thaws.

Taken together, these factors reduce the amount of sap that can flow from tapholes.

Over the past five years researchers at the UVM Proctor Maple Research Center have explored different approaches to reducing these limitations in order to maximize sap yields.

One obvious solution would be to shorten the spout barrel to permit sap to flow more readily from shallower wood tissue. A consequence of this is reduced spout stability and an increased probability of spout heaving during deep freeze periods. [ MORE ]

Farmblox to host open house this weekend in St. Albans

Peter Gregg | April 26, 2023

ST. ALBANS, Vt.—The Farmblox folks are inviting sugarmakers to visit Holyoke Farm, a Farmblox producer, for a special event this weekend in St. Albans, Vt.

There, sugarmakers can see a monitoring system in action in the sugarbush.

"Get all of your questions answered about the most flexible sugarbush monitoring system on the market and see how you, too, can benefit!" said Farmblox president Marc Printz.

Here's the Open House event page to link to: https://farmblox.ag/open-house

[ MORE ]

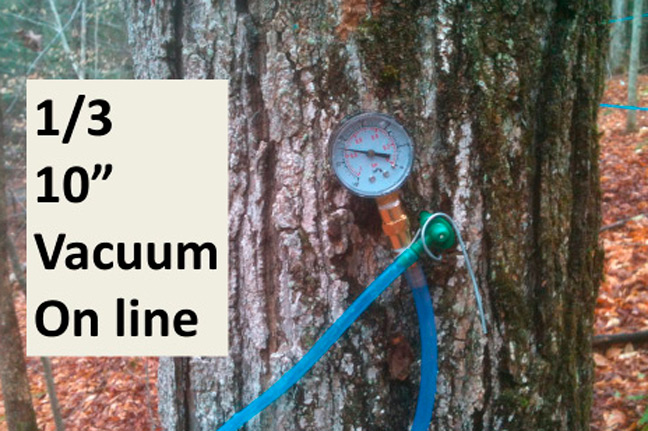

Raging debate on 3/4 pipe

Peter Gregg | April 10, 2023

PLYMOUTH, N.H.—Love it or rip it out?

A debate is starting to swirl between expert installers on the effectiveness of three quarter inch mainline. Some experts are advising that the narrow mainline does not do well transferring sap on vacuum.

“Regardless of the situation, airtight or not, there are always downsides to using 3/4 in. tubing,” said expert Joel Boutin, an advisor for the Quebec Maple Cooperative. Boutin was a guest speaker at the Vermont Maple School in December who emphasized his dislike of 3/4 inch pipe.

Boutin said that 3/4 inch mainline often acts like 5/16ths lateral lines, overfilling with sap and taking up too much space for air. He said big bubbles will form in the tube and decrease vacuum the further away from the pump.

“3/4 tubing can only carry sap from very few taps with the new yields people can get now,” Boutin told The Maple News. “In fact, it is less than 100 taps if you do more than 6 lbs per tap." [ MORE ]

Many sugarmakers sticking with 3/16 tubing

Peter Gregg | March 29, 2023

BOW, N.H.—The reputation of 3/16ths tubing has taken a beating the past couple of years, with sugarmakers gloriously ripping it out of their woods and declaring it a short lived fad.

But there are plenty of sugarmakers that have stuck with the natural vacuum technology, and say that it works for them, and is effective in getting high vacuum from gravity instead of a pump.

The key? Lots and lots of slope.

“Yes it seems the better the slope the better it works and less likely it is to plug up,” said Brandon Daniels of Daniels Pure Maple Syrup in Grassy Meadows, W.V.

Daniels is something of a 3/16ths guru in the Mountain State, where the narrow tubing still rules.

“We are blessed to be able to tap trees on eight properties and we have 2,500 taps on CDL 3/16 natural flow vacuum,” he said.

West Virginia has some of the steepest slope in the Maple Belt, which is why, anecdotally, the technology seems to work there.

[ MORE ]

Tips from Glenn: Goodrich shares his secrets

Peter Gregg | February 14, 2023

PLYMOUTH, N.H.—Sugarmaking legend Glenn Goodrich was the featured speaker at the NHMPA annual meeting on Jan. 21, offering advice on tapping, vacuum and boiling.

“Getting a true round hole in the trees is essential,” Goodrich told producers on his tapping methods. Goodrich has a 160,000-tap operation in Eden, Vt. and Cabot, Vt. and is recognized as one of the U.S.’s premier sugarmakers, winning countless awards.

Goodrich says as he and his crew of tappers march from tree to tree, he estimates he taps a tree in 35 seconds before moving to the next one.

“I fire the drill to the highest speed the drill can spin,” he said, before sinking it into the tree at a maximum depth of no more than 2 inches, or sometimes just one inch on marginal trees.

After the hole is drilled, he uses a nylon-headed tapping mallet to knock in a spout, but with not too much force.

“It’s all in the wrist,” he said. “We’re not knocking in the spout with a 24-ounce Estwing hammer as hard as we can. Don’t do that.”

He said most taps usually get “six hits,” with the mallet.

Once he’s tapped, the vacuum generally runs continuously at the farm.

“I will shut off the pumps only if I know the trees will be frozen for at least 10 hours,” he said. [ MORE ]

What to do about weepy tapholes?

Peter Gregg | February 10, 2023

FAIRFIELD, Vt.—What to do about weepy tapholes?

As sugarmakers across the U.S. race into the woods this week during an unusual warm-up, some are scratching their heads over a common phenomena—sap leaking out of the taphole and spreading around the trunk.

Expert tappers generally agree that the leaks are caused by poorly drilled holes.

“Wobbly or oval holes, I would say is the cause,” said Evan Branon of 80,000-tap Branon Family Maple Orchards in Fairfield, Vt. Branon is the inventor of the Precision Tapper, a drill attachment sold by CDL that helps the sugarmaker drill consistent and straight holes in the tree.

Still, for those who don’t own that equipment, sugarmakers can ensure proper holes by using good technique.

“We always want to use two hands to steady the drill,” said 160,000-tap sugarmaker Glenn Goodrich of Goodrich Maple Farms in Cabot, Vt. who led a seminar on tapping at the New Hampshire maple school last month.

Goodrich said that if a sugarmaker finds a weepy hole after drilling, he/she should not go back and pound the tap in harder with the mallet.

“Just leave it alone and check back on it in a few days,” he said, suggesting that the hole oftentimes will seal up on its own.

[ MORE ]

Maxed out sap? Trees can handle it, say researchers

Peter Gregg | January 5, 2023

UNDERHILL CENTER, Vt.—Are the trees maxed out on sap production? Not yet, say experts.

With several sugarmakers starting a season in November or December and pulling sap from the same trees and same tapholes all the way to late April with high vacuum running every single day, questions are being asked about the ultimate sap capacity of a tree.

“Are we at the limits of extraction? No, I don’t think we are there yet,” said Dr. Timothy Perkins, director of the UVM Proctor Maple Research Center, during an online Q&A session last month.

Dr. Abby van den Berg, also of the Proctor Center, concurred.

“There is a question of the reservoir—we don't know what is there,” she told sugarmakers.

“We think we are taking a reasonably small percentage of the tree’s reserves.” [ MORE ]

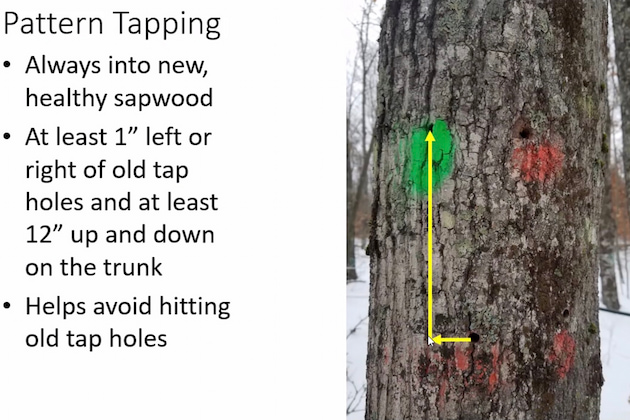

Sugarmaker endorses “pattern tapping”

Peter Gregg | December 22, 2022

DUNMORE, W.V.—Adam Taylor of Frostmore Farm in Dunmore, W.V. practices sequential or “pattern” tapping by marking the tapholes from year to year with colored paint.

“We tend to move in the same direction every year, always to the right, so we dont get partitioned wood,” he said.

Taylor says he also likes to tap “really high in the air” to avoid tapholes from long ago where buckets were once hung from this tree.

“We get good sap quality every year,” Taylor said. [ MORE ]

Early spout deployment ok'd by Proctor researchers

T.D. Perkins, W.T. Bosley, A.K. Van Den Berg, S.J. Abair | September 12, 2022

UNDERHILL CTR.—It is well recognized that spout and dropline sanitation heavily influence sap yields in maple tubing systems.

The drop, including both the tubing and spout collectively, accounts for almost 90% of the sanitation effectiveness in terms of sap production, while the lateral line and mainline have only a small influence on yield in terms of sanitation.

Of this, the spout is by far the most important component, although annual replacement of the spout alone is not enough to achieve maximum production on used droplines.

[ MORE ]

From Pails to Pipelines:

Paul Post | June 26, 2022

BURLINGTON, Vt.—If the maple world ever creates its own version of Mount Rushmore, the tubing pioneers from the 1950s would make excellent candidates.

Nelson S. Griggs and George B. Breen of Vermont, and Robert M. Lamb of Central New York, led the way with development of plastic tubing for sap collection, which laid the foundation for today's highly-efficient, modern production systems.

Historian Matthew M. Thomas, PhD, discussed their work and the evolution of sap gathering in a fascinating online presentation, "From Pails to Pipelines: The Origins of Plastic Tubing in the Maple Syrup Industry."

Thomas created the website MapleSyrupHistory.com and has authored two books, "A Sugarbush Like None Other" and "Maple King: The Making of a Maple Syrup Empire."

[ MORE ]

Maple 101: Expanding through tapping tenure agreements

Mike Rechlin | June 1, 2022

FRANKLIN, W.V.—The issue of tree access can be problematic for many maple producers.

Just like leasing pasture to support a growing herd of cows, many maple producers lease trees to support increased production.

This allows syrup producers to expand production beyond the forest resource they have available on their own lands.

Depending on the demand for trees to lease, a landowner can expect from $0.50 to $1.00 per tree.

A good sugarbush can have 70 taps per acre, realizing an annual income to the landowner of between $35 to $70/acre.

[ MORE ]

Betting on his buckets: N.H. producer taps early

Peter Gregg | February 16, 2022

JAFFREY, N.H.—Betting on his buckets.

A New Hampshire sugarmaker plans on rejuvenating tap holes later this season after taking what some would say is a risky move tapping trees at the beginning of February and hanging buckets.

“I’d rather go early,” said Bud Taylor, during a tour for The Maple News on Saturday.

Taylor hung his 52 buckets, mostly the plastic Lapierre brand, on February 1. [ MORE ]

Tapping tip: Cornell experts recommend 'Pattern Tapping'

Peter Gregg | February 3, 2022

LAKE PLACID, N.Y.—Tappers this season should try pattern tapping and marking old holes with paint.

That was the advice from Adam Wild of the Cornell Maple Program, who led a discussion on tapping during the annual meeting of the Massachusetts Maple Producers Association last week.

Pattern tapping is recommended so sugarmakers avoid hitting old tapholes.

“The reason we use pattern tapping is it helps eliminate hitting non-conductive wood,” he said. [ MORE ]

Experts offer pre-season sugarbush tips

Peter Gregg | January 5, 2022

HEBRON, Ct.—Straight, tight and downhill.

That was the simple advice to sugarmakers from retired Leader Evaporator legend Bruce Gillilan.

Gillilan led a tubing demonstration this fall in sugarmaker Ron Wenzel’s spectacular 412-tap bush in Hebron, Ct.

Gillilan said when determining what trees to tie into laterals, outstretch one’s arms up the hill and only connect trees that fall in between.

Other tips? Laterals should only connect between three and five taps per run, he said. Sometimes more if using 3/16ths.

Experts also say to use 36 inch droplines to reach more surface area of the tree, avoiding non-conductive wood. [ MORE ]

Don't forget the dead end tees

Peter Gregg | November 16, 2021

EAST CONCORD, N.Y.—Putting up new lines this fall? Don’t forget the dead end tees.

At maple shows this fall, sugarmakers were being reminded about the benefits of the common dead end tee, also known as the end line tee.

“We love them,” said Nick Wendel of Wendel’s Maple & More, a major Leader Evaporator dealer in western New York.

Dead end tees are identical to conventional tees, but are plugged off on one side. [ MORE ]

Leader introduces new pre-cut drops

Peter A Gregg | October 29, 2021

SWANTON, Vt.—New from Leader dealers this fall, long-asked-for pre-cut drops.

The packaged drops come in expert-recommended 36” long straight lengths without curl from rolled tubing.

Being straight, the drops allow for easy fitting install, Leader says.

[ MORE ]

Fix lines with fittings and a tool, not tape

Peter Gregg | March 11, 2021

SALEM, N.Y.—Just say no to tape.

Experts advise the best way to fix leaks on a pipeline system is with a tool and a fitting, not black electric tape.

“It is fine as a temporary fix, but WAY better to do it right and cut out the leak and put in a fitting,” said Dr. Tim Perkins of the UVM Proctor Maple Research Center in Underhill Center, Vt. [ MORE ]

Fast! Lapierre touting new mainline FlexClip fitting, installs in less than 30 seconds

Peter Gregg | November 26, 2020

DANBY, Vt.—Lapierre Equipment is touting its new FlexClip mainline entrance fitting designed to be fast, easy and fun to install.

It’s the latest industry offering in the race to create leak proof saddles.

“We claim it’s the fastest install on the market,” said designer Jean Francois (Jeff) Goulet, research and development man at the company, along with company founder Donald Lapierre and son Carl Lapierre. “You just click, screw and drill.”

The black nylon fitting features a pre-stuck-on gasket that secures and self-aligns tight to the pipe. [ MORE ]

Sugarmaker shares experiences with 3/16 sanitation

Art Krueger | September 3, 2020

SHREWSBURY, Vt.—My family’s sugarhouse finally made some significant breakthroughs using 3/16 tubing.

We managed to completely empty our woodshed of 30 cords and needed to scrounge several cords more to finish up. Certainly a measure of success since, after all, emptying the woodshed is the real objective.

Additionally, we’ve had our best year ever reversing the disappointing trend of the past several years.

We’ve even had to sell over 5000 gallons of sap to a neighbor as we were not able to boil it down fast enough.

[ MORE ]

Avoid stained wood when tapping

Peter Gregg | August 6, 2020

NEW CASTLE, Ind.—Sugarmakers are encouraged to use longer drops, shallower tapholes and spend more time looking for good tapping surface when they begin tapping for the 2021 season.

That's the message from University of Vermont Extension maple specialist Mark Isselhardt when he spoke to Indiana producers during the annual meeting of the Indiana Maple Syrup Producers Association in New Castle, Ind. last winter.

“You will get 75 percent less sap if you tap into stained wood,” Isselhardt said.

Indiana sugarmakers who tend to use sap bags or buckets rather than pipeline in their flat woods are better suited to spend time seeing how each tree is producing.

“On buckets you know what each tree is doing whereas on tubing it all blends,” he said. [ MORE ]

Sugarmaker shares experiences with 3/16 tubing sanitation

Brandon Daniels, CDL West Virginia & Virginia | July 22, 2020

DAWSON, W.V.—There has been much discussion and some research given to 3/16” and the reduction in flows that most see after the first season.

The information in this article will not be referred to as research, but it will be presented to help maximize your production on 3/16” tubing in seasons two through ten.

Before we jump into that, I will provide a little more information on our facilities and my background.

I started producing maple syrup over thirty years ago with a 2x3 stainless pan in the back yard and ten taps as a young teenager.

This has grown to a modern state of the art operation.

I am running 2,400 taps +/- 10 on 3/16” tubing in five different areas. These taps run into round bottom stainless tanks produced for maple sap.

In all of the areas we have taps, they are within approximately 1.5 miles of each other.

In all five of these locations, there are taps on slopes that face more than one direction and on the 2,400 taps, we have taps that face every direction on the compass. [ MORE ]

Sapline and spout recycling program in Northern Vermont

Richard Backer, Northwest Vermont Solid Waste District | May 26, 2020

GEORGIA, Vt.—Sugarmakers can recycle old tubing this spring instead of throwing it out with the trash.

The Northwest Vermont Solid Waste District (NWSWD) operates a small Material Recovery Facility (MRF) located at its administrative office adjacent to the Interstate 89 - Exit 18 interchange in Georgia, Vt.

The district is a municipally chartered organization fully serving 19 towns in Grand Isle and Franklin counties. NWSWD has an ongoing modest program to recover and recycle HDPE sapline.

Small and large syrup producers and county associations are encouraged to call NWSWD with inquiries or questions on recovery and recycling HDPE sapline.

Please call NWSWD at 802.524.5986.

If the sapline is clean, without contaminate plastics including spouts, tees or PVC we will take tubing from anyone in the state.

Sugarmakers in other states are welcome to bring their tubing to us as well, as long as it's clean.

[ MORE ]

Vermont sugaring experts offer tapping tips

Peter Gregg | March 3, 2020

UNDERHILL CENTER, Vt.—Town Meeting Day in Vermont, this year March 3, has traditionally been the day sugarmakers get back in the woods to start tapping.

While that old adage is not as true as it once was, with most bigger operations tapping in January or February, many sugarmakers will be out drilling this week in Vermont and across the U.S. Maple Belt.

Meanwhile, industry experts from Vermont were on the pre-season meeting circuit this winter touting good tapping practices.

“Proper tapping is critical,” said Dr. Timothy Perkins, director of the Proctor Maple Research Center as part of the University of Vermont.

[ MORE ]

UVM compares 3/16” and 5/16” tubing sanitation

T.D. Perkins and A.K. van den Berg, University of Vermont Proctor Maple Research Center | January 3, 2020

UNDERHILL, Vt.—It is well recognized that microbial contamination of tubing systems can result in a substantial loss in sap yield if untreated.

Over a decade of research and maple industry experience has produced a range of possible strategies to address sanitation-related issues in 5/16” tubing systems (Perkins et. al. 2019).

Although rapidly adopted by many maple producers, due to the relatively short time period in which it has been in widespread use, there is far less understanding of sanitation in 3/16” tubing systems (Wilmot 2018).

To address this knowledge deficit, we conducted a multi-year study at the UVM Proctor Maple Research Center to examine sanitation-related losses in 3/16” tubing systems to determine which approach(es) might best mitigate sap losses due to sanitation. [ MORE ]

Sugarmaker weighs in on cleaning 3/16 tubing

Arthur Krueger | August 4, 2019

SHREWSBURY, Vt.—He are my 2019 observations on Calcium Hypochlorite bleach for cleaning 3/16” sap tubing at our sugarbush in Central Vermont.

After the 2018 season we cleaned our 3/16” tubing system with calcium hypochlorite bleach. This bleaching solution is made by adding 1 pound of “Zappit” Cal-Shock 65 to 200 gallons of water.

On 80 percent of the sugarbush we cleaned the system by pumping up air and the bleach solution through the laterals. Later we cleaned the drops by squirting bleach solution into the spouts using wash bottles.

These spouts were either replaced with new spouts or used bleached spouts for 2019.

(I found that it is possible to easily reuse a 3/16” fitting by boiling it and removing the bit of attached tubing with pliers. The fitting is not damaged by this treatment and is able to maintain high vacuum. We found no difference in performance between these used bleached spouts and brand new spouts.) [ MORE ]

November tappers might go again

Peter Gregg | October 25, 2018

HOBART, N.Y.—With the calendar turning to November, some sugarmakers are getting ready to start their season.

“We might do about 2500 next week,” said Ben Holscher of Roxbury Mountain Maple in the Catskills region of New York.

Last year the Holschers tapped November 15.

Their effort was not necessarily part of a “fall tapping” experiment, but rather to get a very early start on the 2018 sugaring season.

“We’ve been tapping earlier and earlier in January anyway,” said Ben Holscher, 28, one of eight siblings in the Holscher family. “So what’s it going to hurt going a month or so earlier than that? Might as well.”

“Yeah, it’s been weird,” said Dave Holscher, family patriarch, during a boil last Dec. 6. “We’ve had better sap weather the past three weeks then we did all last year during sugaring season.”

In their valley, November and early December gave them a long three week stretch of perfect freezing nights in the 20s and daytime highs in the 40s.

Trees were gushing.

[ MORE ]

Spout color – Does it matter?

Dr. Timothy D. Perkins, Abby van den Berg, Mark Isselhardt, Brian Stowe and Wade Bosley | Sept. 28, 2018

UNDERHILL CENTER, Vt.—Among the many things that are debated in the maple industry, the effects of spout color on sap yield seem to have as many opinions as there are colors in the rainbow.

Spouts from maple equipment manufacturers are now available in a wide range of colors. Often this selection of color is simply a tool for large-scale producers to keep track of different tappers by assigning them a color, but producers also want to know if spout color has any effect on sap yield.

There has not been a lot of recent research on the subject. Centre Acer conducted a study a few years ago, which concluded that white spouts produced 7% more sap than black spouts (as reported by CDL in their 2018 equipment catalog, page 10).

However, there is likely to be variation from one year to the next depending upon the weather regime experienced during each season. Other factors such as spout design, manufacture, and overall spout/tubing sanitation levels are also likely to slightly affect the results.

[ MORE ]

Strategies for maintaining high sap yields with 3/16 tubing

Tim Wilmot | August 3, 2018

Sap yields from 3/16” tubing on a slope compared to yields from 5/16” tubing are generally very good in the first year, particularly with gravity tubing, but also in many cases when using a pump—as described in two recent articles in The Maple News.

However, yields reported by many users begin to decline, usually by a moderate amount, after the first year. This is particularly true if the tubing is not cleaned at the end of the season.

In part, this is due to the nature of the tubing, which holds onto sap much more tightly than 5/16” tubing, generating natural vacuum in this manner; in some cases it also holds onto sap containing bacteria and yeasts. [ MORE ]

3/16ths guru Tim Wilmot: Using 3/16th tubing with a pump

Timothy Wilmot Researcher, Dominion & Grimm Inc. Retired, University of Vermont Extension Maple Specialist | Jan. 25, 2018

In addition to the advantages that 3/16” tubing provides in creating natural (gravity) vacuum on a slope, there is also an advantage that small diameter tubing can provide in some pumped systems. As is true with an all gravity system, the goal is to maximize vacuum at each taphole. Research has shown that an increase in vacuum at the taphole is accompanied by a steady increase in sap production—the relationship is about 5% more sap for every additional inch of mercury. In many pumped systems, because of friction loss and the capabilities of the pump itself, the vacuum at the taphole is less, sometimes much less, than the maximum that is possible at that elevation.

On a slope, the vacuum that can develop in 3/16” lines can increase what is achieved in the mainline by the pump, and this increase may boost production. The vacuum in the small lines is developed by the weight of the sap, while the vacuum in the mainline comes from the steady removal of air by the pump; together they form what I call a hybrid. This type of system is somewhat newer than the all gravity 3/16” system, and its design, for example the optimum number of taps per line, is less straightforward.

This article summarizes the research that I have conducted on 3/16” hybrid systems; unless otherwise noted, all of the results reported here are my own.

[ MORE ]

3/16ths guru Tim Wilmot. The gravity of it all.

Tim Wilmot, University of Vermont Ext. Maple Specialist (retired) Researcher for Dominion and Grimm Inc. | Jan. 13, 2018

The use of 3/16” tubing for sap collection began as a series of experiments that I conducted while working at the University of Vermont Proctor Maple Research Center.

The goal was to devise a gravity sap collection method that would improve production for sugarmakers with small operations who typically collected much less sap than producers using vacuum pumps.

Over the past 8 years I have continued to conduct research with this tubing in an effort to learn more about its potential uses and possible shortcomings, both for gravity and pumped sap collection.

[ MORE ]

Sugaring in December

PETER GREGG | Oct. 1, 2017

Some call it defying Mother Nature, others would call it taking advantage of her, but the fall tappers are at it again.

“I only planned on having enough sap to boil on the stove,” said Cody Armstrong, one of the few brave souls who tapped trees this fall. “I thought it would be cool.” [ MORE ]

The Take Down Master

Peter Gregg | April 2017

It’s hard to believe Tony Van Glad is still smiling.

Van Glad, a 6,300-tap producer in the Catskills region of New York, is one of the few sugarmakers who put up and then take down their entire pipeline system every season. [ MORE ]

Sugarmakers invent gadget for easy droplines

Caleb Schrock & Jeremy Swartzentruber | December 2016

We have done tubing installations and made droplines so we know how time consuming, strenuous and monotonous making drop-lines can be.

We knew there had to be better [ MORE ]

Man vs. Squirrel

Peter Gregg |

The arch enemy of sugarmakers is the squirrel.

More than maybe any other force of nature—a bad season, a bad wind, fallen branches—it’s the hordes of gray and red squirrels that cause the most costly damage in the woods, chewing up tubing, fittings and spouts. [ MORE ]

Results in from 2016 3/16” tubing research

Stephen Childs, NYS Maple Specialist |

The 2016 maple sap season offered an interesting look at the effects of 3/16” tubing on vacuum without significant elevation drop and some comparisons of 3/16” tubing with and without the addition of mechanical vacuum. [ MORE ]

3/16 tubing thoughts and observations

Arthur G. Krueger, P.E. |

In the December 2015 issue of Maple News, a person discussing 3’16” tubing said that one needed 10’ of fall for the system to work. At best, 10’ would only give a vacuum of 9” of mercury (9” hg on your vacuum guage). Not exactly a high vacuum system. 40’ or 50’ of fall is required for high vacuum. If set up right, these systems will develop a high vacuum in the tubing itself without a pump or releaser. [ MORE ]

Going underground

Peter Gregg |

Mike Ross expects his underground pipeline to last a lot longer than he will.

“You get 150-year life out of PVC pipe,” he said during a 2015 tour for The Maple News at his RMG Family Maple orchard in Rudyard, located in the far right corner of the Upper Peninsula of Michigan. [ MORE ]

Device eases tubing connections

Peter Gregg |

A relatively new invention is going into the woods this sugaring season that eliminates the need for that clunky tubing tool, the necessary evil when it comes to running lines. [ MORE ]