BACK TO HOME

UVM Proctor Page

Aesthetics of sap collecting

Tim Wilmot, UVM Extension |

Each year many new people try their hand at sugaring, and discover how satisfying it is to share syrup made with their own hard work. Most sugarmakers take great pride not only in their syrup, but in the entire process of maple production. Remember that whether you produce 2 gallons or 2000, you represent the maple industry to the public. You are making a specialty food product that is pure and natural, and your maple operation should reflect this fact. It is important to set a standard that gives the public confidence in your operation, even if it is very small.

[ MORE ]

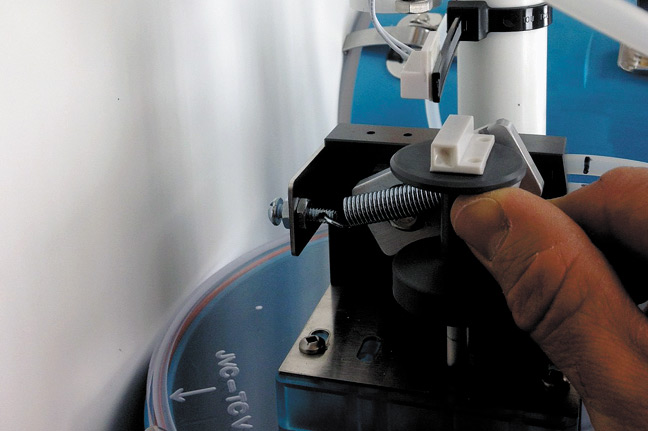

Measuring sap flow

By Mark Isselhardt and Tim Perkins |

Over the past several decades we have used several different methods to measure sap volume. With a bucket it is fairly simple….when the system is under vacuum it becomes more challenging. At the University of Vermont Proctor Maple Research Center, we employ a combination of simple recording counters mounted on mechanical vacuum releasers to measure sap production. We are frequently asked by maple producers for details on how we accomplish this and how they might set up something similar in their operations. [ MORE ]

The 3/16 phenomenon

Tim Wilmot |

Gravity tubing systems typically do not perform well compared to systems connected to modern vacuum pumps; however, there are new options today for creating high vacuum in gravity tubing. As many people know, a system using tubing with an interior diameter of 3/16” has been developed in recent years at the University of Vermont Proctor Maple Research Center and has shown considerable success in a variety of locations. [ MORE ]

Testing tapping depth vs. sap yield

Tim Wilmot |

Although it is one of the more significant factors controlling the amount of sap we collect, there is little current published information that examines the relationship between taphole depth and sap yield under vacuum conditions. [ MORE ]

Cloudiness’ affect on refractometer measurements

Mark Isselhardt and Timothy Perkins |

Accurately measuring density is critical to the production of pure maple syrup. Historically, sugarmakers have relied on thermometers and or hydrometers to determine when syrup has reached the desired density. These instruments remain valuable tools today. Refractometers are another tool that can be used to make precise density measurements. [ MORE ]

Using Smartrek vacuum monitoring system

By Timothy D. Perkins and Mark L. Isselhardt |

Four main factors influence sap yields from maple trees. First there is the tree resource itself. Secondly, weather conditions suitable for stimulating sap flow (freeze-thaw events) must occur to start the process. Thirdly, excellent spout and tubing sanitation practices. Finally, higher vacuum levels. [ MORE ]

Should droplines be replaced when using check valve adapters or spouts?

Timothy D. Perkins |

The Leader Check Valve Adapter (CVA) and Leader Clear Check Valve Spout (CVS) are designed to reduce the amount of sap backflow (sap movement back towards the taphole during pump shutdown, leaks, or releaser dumps). [ MORE ]

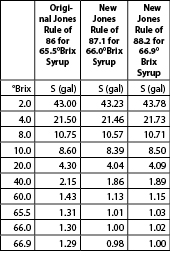

The ‘Jones Rule of 86’ revisited

Timothy Perkins and Mark Isselhardt |

The Jones “Rule of 86” was devised in 1946 by C.H. Jones, a scientist and educator at the University of Vermont.

Originally it was incorporated into a poem that taught several best management practices in a humorous way (see “The maple rule of eighty-six”, reprinted on pages 18-19 of the December 1967 edition of the “National Maple Digest” and pages 129-132 of Maple Sugarin’ in Vermont, by Betty Ann Lockard 2008). [ MORE ]