Sugarmaker Profiles

At Papa John's, life’s passion about to get bigger

Sugarmaker has aggressive plan that would nearly double his output

By PAUL POST | DEC. 28, 2017

Mark Turco goes to work to make a living.

Making maple is his passion.

As a young kid, the Mount Holly, Vermont resident would pedal his bike down the road, and watch with fascination as steam billowed from a neighbor’s sugarhouse and the sweet aroma of boiling sap filled the air. In eighth grade, Turco fashioned his own evaporator out of a 55-gallon drum, which he made in a shop metals class. Right out of high school, he purchased his first real evaporator -- a 4-foot by 14-foot model -- for $3,400 that he earned doing odd jobs and selling syrup.

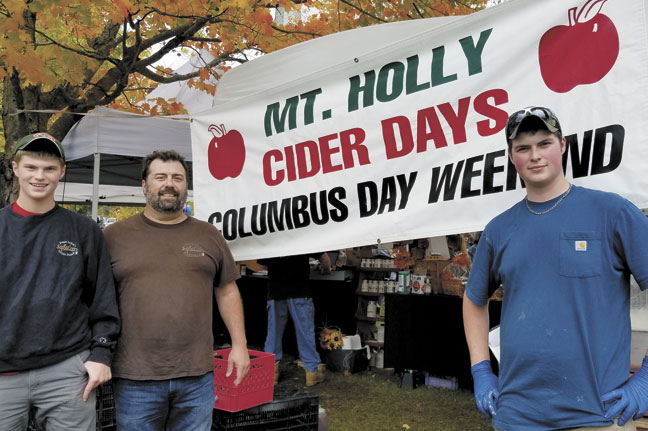

Turco, 52, is amazed how far he’s come since then. He now owns and runs Papa John’s Sugar Shack with his wife, Amy, and their sons Mark Jr. (19) and Austin (17). The business is named in honor of Mark Sr.’s late father.

“Twenty years ago I never would have dreamed I’d be where I am today in the industry,” he said. “I’ve had this passion for maple and the maple industry my entire life. It seems to grow every year. I’d have 50,000 taps if I could. I just don’t have enough trees or land.”

But an aggressive growth plan is in the works. After reaching a 5,000-gallon production goal a few years ago, Turco hopes to nearly double output by expanding from about 11,000 to almost 20,000 taps over the next couple years.

“It’s time to make the shift,” he said.

The business must grow to remain sustainable because both sons are actively involved and want to stay that way after getting out of school.

Mark Jr. is currently enrolled in a manufacturing curriculum at Vermont Technical College in Randolph. “I like it all,” he said about maple. “I’ve been exposed to it all. I like seeing the process, how it goes from tree to table and the marketing part of it.”

Austin is taking first-year VTC courses while still enrolled at Black River High School, where he’s a senior. “Personally, I like to be out in the woods, maintaining lines and tapping,” he said. “I like to find the most efficient, cost-effective way to do things.”

This fall, Austin is helping install main line sensors on land the Turcos lease from the State of Vermont at nearby Okemo State Forest. Sensors, which work off a satellite system, show vacuum leaks and tank levels as well as temperatures in the sugarbush. The technology saves time, labor and money by cutting down on the need for personal inspections.

As retirement nears for Mark Sr., he could eventually hand things over completely to his sons, although that’s still several years away.

For now, they’re busy learning all aspects of the business from him.

Turco’s formula for success has been steady, consistent growth without overspending. In 1995, he replaced his original 20-foot by 24-foot sugarhouse with a larger 32-foot by 45-foot structure. Sap is boiled in an oil-fired Leader Evaporator with a Steam-Away.

In 2012, he installed Lapierre reverse osmosis equipment.

Retail, including online sales, accounts for about 70 percent of Papa John’s business. The rest is sold wholesale to numerous stores, restaurants and inns in an area stretching from Killington to Ludlow to Bennington. Much of their syrup is consumed by the thousands of skiers who visit Vermont each winter.

“The product sells itself,” Mark Sr. said. “When people have breakfast, they ask where the syrup comes from. That’s how we keep growing clientele.”

From May to October, the Turcos attend numerous events such as Art in the Park in Rutland, Bennington Garlic Festival and Chester on the Green, a popular fall arts and craft festival. Of course, they were among the many vendors set up at the recent annual Mount Holly Cider Days, where visitors flocked to buy their syrup and value-added products.

“We enjoy being out there, explaining the process, explaining what Mother Nature gives to us,” Mark Sr. said. “A lot of people don’t understand how maple is made. They think you tap a tree and syrup comes out.”

“Value-added products are a great big piece of the pie,” he said. “We sell hundreds of pounds of maple cream and sugar. This summer we sold 600 to 800 containers of maple sugar alone. The biggest bang is cotton candy, especially at festivals. We also have a maple cream cheese that we let people sample on Saltine crackers. They absolutely love it.”

Of course, as Papa John’s expands, the business will have to find new outlets for its increased production. However, Turco Sr. believes there are plenty of untapped markets.

“There are limitless opportunities for the maple industry overseas,” he said. “There are little corners of the world where people have never tasted syrup.”

Some of Papa John’s syrup is already going around the globe through Hannah’s Gold, a charitable foundation set up by Olympic gold medal-winning snowboarder Hannah Teter of Belmont, Vt., which neighbors Mount Holly. The non-profit organization helps the village of Kirindon, Kenya by building schools, digging fresh water wells and providing water filtration.

Teter grew up making maple with her parents and is now using it to “Sweeten the World” one bottle at a time. Much of Hannah’s Gold syrup comes from Papa John’s.

Mark Sr. can’t help being surprised at how popular maple has become and the industry’s growth since he started out. “We are seeing more and more people get into the industry,” he said. “People who purchase maple products are more aware of the health benefits.”

However, he’s also concerned about a potential downside to this trend. “Wholesale prices are declining because of technology, which produces higher yields,” he said. “The expansion rate is growing faster than the market. Like any industry, you have ups and you have downs. You’ve got to weather the storms.”

Like anyone else, there are plenty of things Turco Sr. would like to do in retirement some day, like seeing America’s most famous natural wonders, such as the Grand Canyon and Yellowstone National Park. However, maple is in his blood, so it’s hard to imagine him not staying involved when he’s no longer at the helm of Papa John’s.

“I’m never going to lose my love for the maple industry,” Mark Sr. said. “I’d like to help my sons take the business even further.”