Sugarbush Management

Company can map your sugarbush with a drone

Quebec company offers drone mapping services

By PETER GREGG | NOV. 2016

STORNOWAY, Quebec — The future keeps catching up to the maple industry.

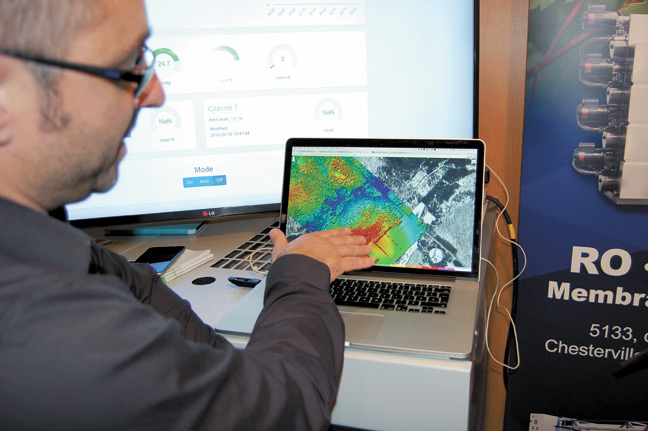

One of Quebec’s leading technology innovators is offering drone services to sugarmakers, helping producers map out their sugarbush with real arial photos and 3D graphic images of sugarhouses.

“As soon as I started seeing the drone industry growing so fast, I started looking at models that I could take to the sugarbush,” said Martin Chicoine, the owner of ErabliTek, a company which specializes in offering sugarmakers monitoring and automation technology.

Chicoine has only been flying his drone since June, learning the controls and configuring the best ways to map out sugarbushes. His partners in the operation are Jose Hallee, a fifth generation sugarmaker and Philippe Lafrance, who does all the computer programming for the company.

“We test and test and test,” he said. “We are mastering speed, precision and imaging.”

Exact location

Chicoine says that up until now, the current GPS tracking technology, where sugarmakers walk their lines with smartphones and then transfer the data to Google maps, is insufficient in telling the sugarmaker exactly where his lines are when he really needs to know.

Google maps gives a general idea of where the lines are, but true arial photography shows the sugarmaker exactly where they are located and what they are next to.

Also, satellite images of sugarbushes offered by Google usually show the bush in the summertime, hiding the lines. And those images are taken from satellites in space.

Chicoine’s drone flies anywhere from 50 feet to 500 feet above the trees, snapping hundreds of photos in just a few minute’s time, zig zagging above the property line.

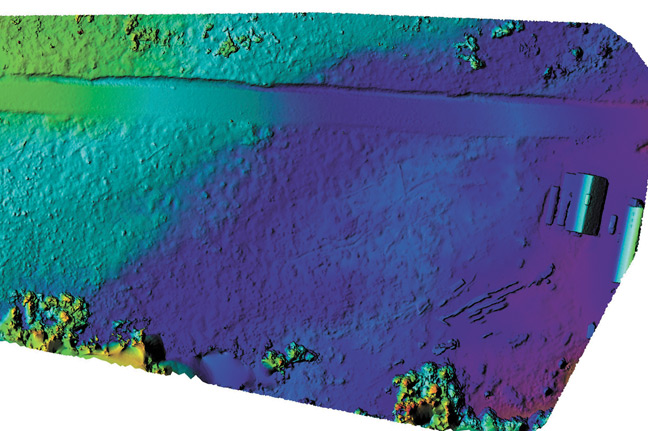

The images are then stitched together into a mosaic, giving the sugarmaker a full picture of his entire sugarbush with all of the lines, pumps and topographical features.

The biggest challenge for the company is programming software to make the drones automatically follow a flight path over the sugarbush. But in a demonstration for The Maple News on Nov. 29, the drone acted like it had a mind of its own.

Endless benefits

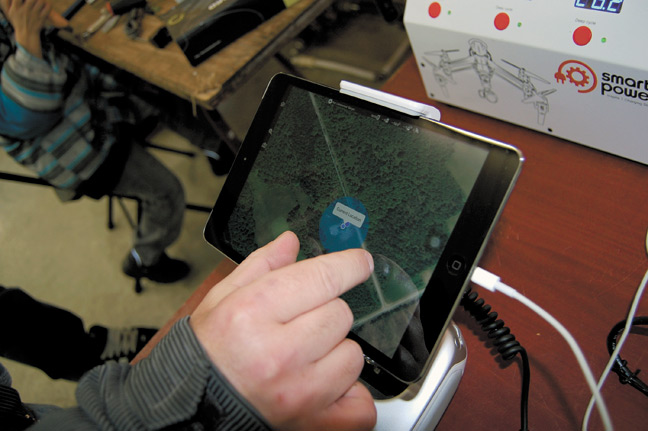

At his 18,000-tap operation in Stornoway, Que., Chicoine launched the drone with a remote control device linked to an iPad. Once airborne, Chicoine simply watched the drone follow its pre-programmed flight path over the trees, 200 feet in the air.

“This part of it is boring,” Chicoine joked, waiting for the drone to finish its job.

The drone, which costs more than $10,000, has a high resolution camera attached to its belly. In the span of just a few minutes, it took hundreds of photographs. It flies with remarkable speed with four small propellers fueled by a battery with about 20-minutes of life.

Chicoine says that the benefits of the technology are endless. Especially for pre-planning install jobs.

“We are going to know before we even walk the woods exactly where to do the installation,” Chicoine said. “We are going to know where to put all the mainlines and the parallel lines. We are going to know the lowest point and the highest point. We are going to know even where to put the pump station and where the vacuum lines will go.”

“We can draw all the lines from our desk,” he said.

Originally published November 2015