UVM Proctor Page

Measuring sap flow

Issue is not only important to producers but researchers as well

By BY MARK ISSELHARDT AND TIM PERKINS |

Running a successful sugaring operation is complex no matter the size. Proper installation and maintenance of tubing, vacuum pumps and releasers are all important to ensuring maximum sap production. Keeping track of the amount of sap being collected is also important for maintaining high yields and minimizing losses. Producers who use vacuum pumps become very good at observing subtle differences in how sap flows into the releaser. Air passing through mainlines, surging flow and partially frozen sap can all help identify trouble in the tubing system, however actually measuring the amount of daily sap flow can be somewhat more problematic. The curved surfaces of standard sap tanks renders making good sap volume estimates difficult. In addition, the highly dynamic nature of individual sap runs (short period of high flow followed by longer period of very low flow) in a partially filled pipe poses problems for standard flow meters. This issue of measurement is not only important to producers but to researchers who must measure sap volumes with precision to detect any differences between experimental treatments.

Over the past several decades we have used several different methods to measure sap volume. With a bucket it is fairly simple….when the system is under vacuum it becomes more challenging. At the University of Vermont Proctor Maple Research Center, we employ a combination of simple recording counters mounted on mechanical vacuum releasers to measure sap production. We are frequently asked by maple producers for details on how we accomplish this and how they might set up something similar in their operations.

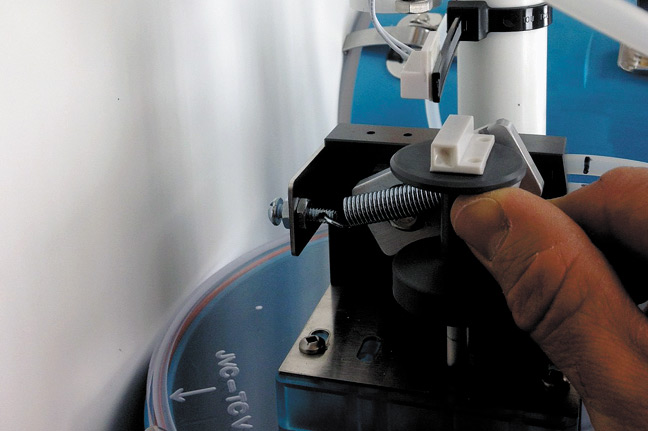

The counter shown in Figure 1 is one method that we have employed for many years. It uses a magnetic window/door switch (like that used in security systems) connected to a small LCD display1. The display and the wired magnetic reed switch are attached to the releaser with a zip tie. The other magnet is attached (glued or mounted with double-stick foam tape) to the top of the float. Each time the magnets come within ½” of each other the counter tallies one dump of the releaser. This counter display shuts off after ~2 minutes to preserve battery life (the device uses one AA battery), but the reading remains in memory until the reset button is pressed. We have successfully used several variations of this type of setup with mechanical releasers, but with a little thought and tinkering, it could be modified for use with other styles.

In order to make reliable measurements its essential that the releasers are calibrated (weight or volume of sap per dump measured precisely) and then not altered during the season (for example, by changing the float location where the releaser dumps).

A simple way to calibrate is by measuring the volume (by weight) of each releaser dump at least 5 times at the vacuum level at which you normally you operate your system. The volume should be within a few tenths of a pound. If the per dump weight is more variable then investigate the cause (leaking flapper, poor vacuum or other seal).

Knowing the total sap produced for a given section of woods is tremendously helpful in determining the impact of leaks, the success or failure of repairs or seeing how effective a given cleaning strategy is at maintaining high yields.

There are several important things to keep in mind when looking at the counter data. The season total sap production will yield a single number for each counter. While that number is important, it is also important to look at how that number was reached. For the purposes of this article it is more important to focus on trends of sap flow rather than absolute sap production. Frequent readers of The Maple News will no doubt be familiar a line graph of cumulative sap yield as we use them often to help describe the results of experiments. All lines start at zero (no sap collected) and end at some point (season total sap produced). The slope of a given line indicates the rate of sap flow (steep=high flow rate and flat=no flow). These graphs can help identify points along the season that may have contributed to the performance (of lack of performance) in that area of the woods. Figure 2 helps illustrate how different two season total sap production can be reached. Each line on the graph represents a separate and reasonably equal block of trees and a single mainline entering the sugarhouse. It is clear from the top graph that the ‘blue line’ area experienced a swift decline in the rate of sap production (less steep flow rate and little change in total sap produced during that time). Compare that with the lower graph that shows a second section of woods that failed to keep pace with the other systems from the outset of the season.

It is essential to keep in mind there are many factors that influence how much sap a given section of woods will produce. The topography, aspect, number of taps, age of tubing system, sanitation strategy and vacuum level for each mainline are just a handful of factors that can have substantial impacts on the final season sap yield.

Given the simplicity and low cost of this system, and enough interest from maple producers, perhaps equipment dealers will start offering counters as optional equipment for their releasers.

A later article will focus on measuring sap from electrical releasers.

1 Magnetic Circuit Counter (#105) $19.95 from The Tally Counter Store, tallycounterstore.com.

January 2015