Tapping & Tubing

Proctor reports on 2023 season barb-spout results

By BY TIMOTHY D. PERKINS & WADE T. BOSLEY | MAY 18, 2023

UNDERHILL, Vt.—The outermost rings of wood in maple trees have the highest sap flow rates and have sweeter sap than the wood found deeper in the tree.

In addition, during the early part of each season there are several periods when thawing is too brief and shallow to allow sap to be collected.

This is because typical maple spouts have elongated barrels that are inserted well into the wood to anchor them in place. While this design feature of spouts reduces the tendency of sap to dislodge during deep freeze periods, it doesn’t permit sap collection during brief thaws.

Taken together, these factors reduce the amount of sap that can flow from tapholes.

Over the past five years researchers at the UVM Proctor Maple Research Center have explored different approaches to reducing these limitations in order to maximize sap yields.

One obvious solution would be to shorten the spout barrel to permit sap to flow more readily from shallower wood tissue. A consequence of this is reduced spout stability and an increased probability of spout heaving during deep freeze periods.

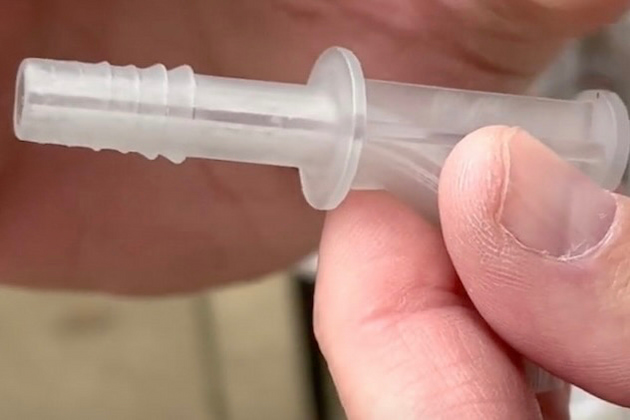

To counter this problem, we designed a spout that incorporates both a shortened barrel and a series of barbs along the shaft to anchor the spout tightly within the wood and bark tissues.

Testing over several years with prototypes machined from polycarbonate rod stock indicated the approach was valid and produced increases in sap yield ranging from 10.8-23.8%. Based upon these preliminary results during development and testing, UVM filed for patents of these design features.

Testing in the 2023 season was completed in several areas across the U.S. and in Quebec on injection-molded prototypes incorporating the shortened barrel and barbs as well as an arc-flow (curved) tubing connection (Figure 1). We are still waiting to hear from several cooperators, so only results from the UVM Proctor Maple Research Center are presented here.

In the first study, 80 trees were selected for study and connected via 5/16” drop and lateral lines to individual large vacuum sap collection chambers.

Vacuum was supplied via a single pump averaging 27” Hg throughout the season. Drops and spouts were new. Half the trees were equipped with normal polycarbonate spouts (with the arc-flow connector) and half with the Barb-spout (with arc-flow connector).

Average tree dbh was 12.1” and equalized between the two treatments. Sap level in the chambers were monitored and sap removed as needed to prevent overflow.

All trees were tapped on the same day by the same person. At the end of the season sap volume and sugar content was measured and added to any amount removed during the season.

Results from this study showed that the Barb-spout produced 12.2% more sap than normal spouts (Figure 2), a result consistent with previous years.

The increase in sap yield observed is anticipated to vary from year-to-year and site-to-site due to seasonal and location differences in freeze/thaw conditions.

Study 2 incorporated 664 trees split across two treatments. The first treatment consisted of three mainlines equipped with normal polycarbonate spouts and nylon tees.

The second treatment also had three mainlines, but these were equipped with Barb-spouts and Arc-flow tees. Sap was measured with individual, calibrated mini-releasers equipped with counters.

Counters were recorded after each sap flow period and reset. Sap totals were calculated for the season.

Results from this study showed a 10.3% increase in sap yield using the Barb-spout (Figure 3).

Sap sugar content was also marginally higher from the Barb-spout treatments. When sap sugar content was factored in with the increases in sap yield, syrup yield across the two studies averaged nearly 13% higher than with regular spouts.

Taken together, these and previous results indicate that the Barb-spout shows significantly higher performance in terms of syrup production compared to normal maple spouts with typically elongated barrels.

It is likely that the Barb-spout will be produced and available for the 2024 maple season via direct mail-order from Middle Valley Maple (Vermont) and through participating maple equipment suppliers.