Tapping & Tubing

Results in from 2016 3/16” tubing research

More good news on the 3/16ths phenomenon

By STEPHEN CHILDS, NYS MAPLE SPECIALIST |

-

2016 maple season, 3/16, tubing, vacuum, elevation drop, comparisons, 5/16, tap, sap, yield, collection, maple, slope

The 2016 maple sap season offered an interesting look at the effects of 3/16” tubing on vacuum without significant elevation drop and some comparisons of 3/16” tubing with and without the addition of mechanical vacuum.

The trials were tapped on February 21st and the first sap flow reading taken on February 25th. The season turned fairly warm with temperatures in the 50s very early in the season and few freezes usually spaced 5 to 6 days apart. These conditions lead to weak sap flows throughout the season and fairly rapid breakdown of attempts to keep the tap holes sanitary.

We also had problems in the first couple of weeks with the vacuum pump performance that was finally corrected with the replacement of the air filter in the oil re-claimer.

These first treatments had four replications with four taps on each replication. This experiment was to compare the yield performance of 3/16” laterals and drops vs. 5/16” laterals and drops with no significant elevation drop and all spouts, drops and lateral were new.

An additional treatment was all new 3/16” only with a new check valve spout in place of the new standard spout. There are no 3/16” check valve spouts that we were aware of so just before the spout a 3/16 to 5/16 tubing connector was added and the usual 5/16 check valve spout inserted. These all operated with an average of about 15” of vacuum early in the season and 22” for the rest of the season.

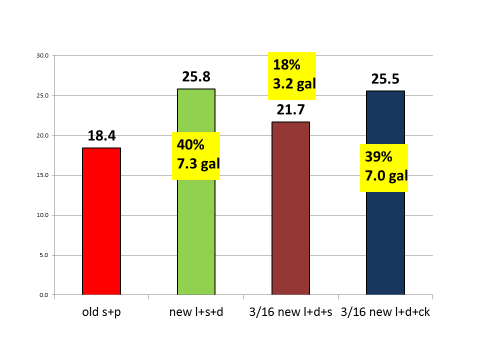

The chart on the front page shows the yield differences:

The first bar on the chart shows the season long yield of the 5 year old spout and 6 year old drop and lateral line at 18.4 gallons of sap per tap.

The second bar shows the season long yield of 5/16” tubing with new lateral, drop and spout resulting in 25.8 gallons of sap per tap. A 40% increase over the old lateral spouts and drops.

The third bar shows the season long yield on 3/16” tubing with new lateral, new drop and spout at 21.7 gallons of sap per tap. That is 18% higher than the 5/16 old lateral spout and drop but about 16% less than the new 5/16. The final bar 3/16” tubing with new lateral, new drop and new check valve spout was 39% better than the old 5/16” tubing but just .3 gallons of sap per tap less than the all-new 5/16” system.

The first question is why the check valve would make this difference. It has been expected that the potential for the tree to pull sap back into the tree from the tubing during the periods when the tree has developed its internal vacuum when it is below freezing may be significantly greater for 3/16” lines than occurs with 5/16” lines.

Tests run with 5/16” lines in the past have shown a pullback of 8” to about 14” of sap. In tests set up in 2016 the sap was pulled back into the tree as much as 12’ with 3/16” line. That represents about 4 times the volume of sap being pulled back into the tree with 3/16” tubing and an increase in the potential area of contamination in the tubing being pulled back. Both could influence the total yield per tap.

Again, lots more to learn about managing these sap collection systems. In these experiments the vacuum was on 24-7 but when the temperatures in the sugarbush falls below freezing the mainlines freeze, usually down near the pump, leaving the vacuum level in the woods 0 until it gets thawed the next warm day.

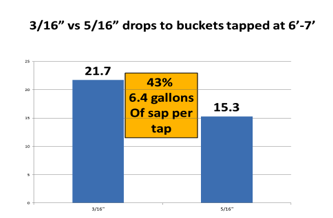

A second experiment involved tapping trees six and a half to seven feet high and running the long drop line to a bucket on the ground. In this case each tree had two taps. One tap a regular 5/16” spout attached to 3/16” tubing and the second tap a regular 5/16” spout connected to a 5/16” drop line. This was repeated six times for a total of twelve buckets, 6 with 3/16” drop and 6 with 5/16” drop. See the pictures below. The season long yield difference between the two systems was 43% more sap in the buckets collecting sap from the 3/16” drop lines or 6.4 more gallons of sap per tap. See the bar chart below.

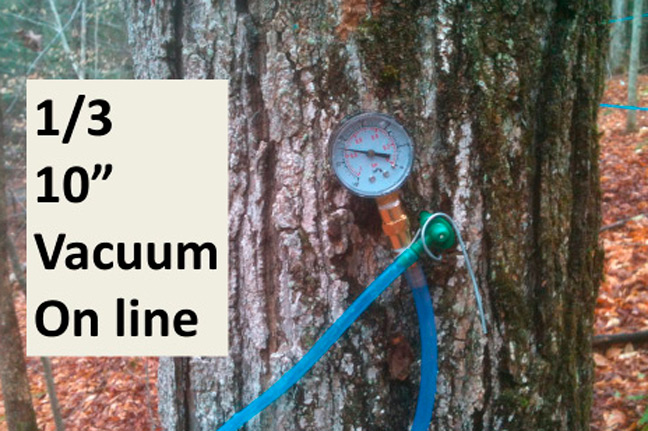

The third plot was not a replicated trial but a demonstration site to see the effects of adding vacuum to a 3/16” line vs. the same line operating with gravity alone. Just one 3/16” line was connected to a vacuum canister where the vacuum could be turned on or off.

The line had 13 taps and included a vacuum gauge at the bottom, one about 1/3 of the way up the slope, one about 2/3 of the way up the slope and the last gauge at the top. The total elevation from the top to the bottom was about 38’. When the vacuum was off at the bottom the bottom vacuum gauge read 0, the gauge 1/3 of the way up the slope read about 15”, 2/3 up the slope read 22.5” and the top gauge 26.5”.

This demonstration was set up on the very end of a very long, problematic mainline at the Arnot Forest so the available vacuum was just 10” on the day this data was collected but it still clearly makes the point. With the bottom gauge showing 10” the gauge 1/3 up the slope showed 22.5”, 2/3 up the slope showed 25” and the top gauge showed 27”. So by adding 10” of vacuum at the bottom of the slope the tap 1/3 of the way up the slope increased 7.5”, 2/3 up the slope gained 2.5” and the top gained just .5” of vacuum.

The amount of yield increase that can be expected by adding vacuum to a 3/16” line with significant slope would depend on several factors.

First, how much mechanical vacuum can you get to the site?

Second, how much natural vacuum is already created by the slope?

Third how many trees are near the bottom of the slope vs. the number that are near the top? The added vacuum will primarily enhance the production of the trees that don’t have much natural vacuum available.

Our experience with vacuum at other sites is that you can expect to increase yield between 5% and 8% for each inch of vacuum you can increase at the tap.

June/July 2016