UVM Proctor Page

Sap flow, wounding and compartmentalization in maple

Trees like to go with the flow

By TIMOTHY D. PERKINS, ABBY K. VAN DEN BERG, AND MARK L. ISSELHARDT | JUNE 23, 2021

UNDERHILL CENTER, Vt.—Our trees like to go with the flow.

The mechanisms of sap flow in maple stems during the springtime are reasonably well understood.

Water is drawn from the soil into the roots, stem, and branches of trees during a freeze cycle as liquid water transitions to ice and gases in the wood contract.

Upon thawing, gas bubble expansion within wood fibers, gravity, and osmotic factors from conversion of starch to sugar create pressure within the stem.

If a taphole is present, sap will flow out due to the difference in pressure from the inside to the outside of the tree.

Sap always moves from areas of high pressure to areas of lower pressure.

This process of developing stem pressure is an adaptation of maple trees to living in the cold.

Freezing temperatures during the winter cause dissolved gases in vessels to come out of solution, forming emboli (bubbles).

Air bubbles in vessels disrupt the water column and render affected vessels incapable of efficiently transporting liquid.

Stem pressure develops in maple trees in order to eliminate bubbles.

Other cold climate trees deal with emboli differently, but the goal of eliminating air bubbles in the sap conducting system is the same.

With the emboli in the vessels eliminated, a continuous water column is restored, and maple trees can efficiently move water from the soil to the crown during the growing season.

Maple trees used for sap production must contend with another problem, the wounds created by tapholes.

If not dealt with in some manner, water transport could be reduced or compromised. So how does a tree react to a taphole wound?

When a taphole is drilled, a wound response is elicited.

We don’t think of trees reacting to things quickly, but the signal that initiates the wound response is triggered quickly.

The end goal of the response is to “wall off” or “compartmentalize” the wound. The hole itself is never filled with new tissue in the way animal heal wounds.

Instead, trees alter the physical and chemical environment in the tissues surrounding the wound in order to form a barrier.

Trees form new structures (gum plugs, tyloses) to seal off severed vessels.

Antimicrobial compounds are deposited in the zone around the wound.

These make the affected area less hospitable, preventing disease and decay organisms from becoming established and proliferating within the tree.

One consequence of building these chemical and physical walls is that the area around the wound is rendered incapable of transporting sap.

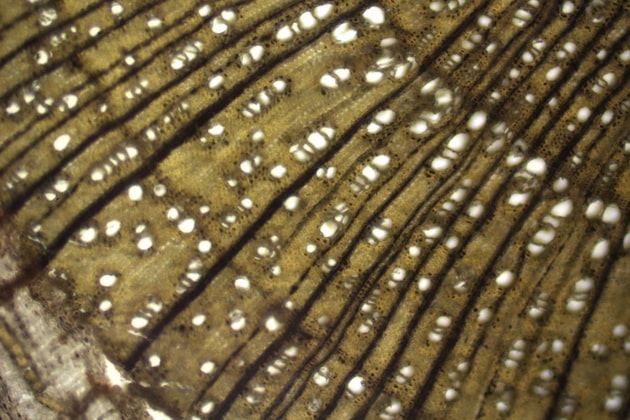

Wood affected by this process appears darker in color and is referred to as “stain”, “stained wood”, or “non-conductive wood” (NCW).

Producers experience the result of this process as reduced sap flows later in the production season, even if the weather conditions remain good for sap flow.

This is known by maple producers as “taphole drying.” Although good spout/dropline sanitation practices can help delay the onset, when temperatures and microbial growth rise later in the season, the wound response accelerates, and sap flows lessen dramatically.

Over the subsequent months, the tree continues to strengthen the walls around the wound.

Because vessel elements are vertically oriented and are fairly large in comparison to other tissues (maple vessels are generally under an inch long, but can rarely grow up to 10-12 inches), staining is greatest in the up/down directions away from the taphole.

To each side of the taphole, the wound is typically well contained, so stain extends only a short distance laterally.

Inward (radially), the stain typically extends a bit further than the taphole itself.

Except in the area of the hole itself, the new ring of wood formed during the following growing season forms the final barrier to compartmentalize the wound. Although the majority of the stain completes development in the growing season after sugaring, in some cases the column can continue to grow for a few years after tapping.

With smaller spouts and good growth rates, tapholes may close the opening in a single season. With large spouts and slow growing trees, complete taphole closure may take several years.

As long as tapping is done in a sustainable fashion so that trees are able to grow enough new conductive wood each year to compensate for the loss of functional volume to NCW from tapping, the wound is not terribly detrimental to maple trees.

If a producer taps into an area of NCW, less sap will be collected. The loss in yield is directly proportional to the amount of stained wood hit.

If only a small amount of stain is hit in the deepest part of the taphole, a minor loss of sap is expected. If a lot of stain is hit, sap yields will be low.

Producers should monitor the amount of stain encountered while tapping by inspecting drill shavings. Whether to put in a new tap if a lot of NCW is hit is a difficult question.

It is generally not recommended if it is difficult to find good tapping locations on previously heavily-tapped or slow-growing trees.

It is also important to remember that when a taphole is drilled into pre-existing NCW, the amount of new NCW formed in response will be much larger than if a taphole was drilled into clear sapwood – the pre-existing NCW contains no living cells to mount the wound response.

Because sap cannot flow through the affected NCW, what happens to water transport in that zone? Do the branches and leaves supplied by those vessels die?

Vessel elements are not simple, straight pipes. Rather, they are groups of pipes that have a high degree of interconnectedness and therefore a great deal of redundancy.

While the flow in unaffected vessel elements is mostly upward, some lateral movement of sap occurs at the transitions from one vessel element or group of elements to another.

Therefore, sap is able to flow around stained areas, much like water will flow around an island in a stream.

The rate of sap flow increases in the immediate vicinity of the NCW, and slows down beyond this area, but flow itself is unimpeded unless NCW is actually tapped into or NCW is so extensive that blockages dominate.

For all these reasons, maple producers are fortunate that the trees we use are well adapted to winter and to sustaining repeated injury and the loss of a small amount of sugar each year.

Several educational videos relating to tapping and staining can be found in the “Keys to High Sap Yields” playlist on the UVM PMRC YouTube Channel at: https://www.youtube.com/c/UVMProctorMapleResearchCenter

(originally published in the VMSMA Spring 2021 Newsletter, reprinted with permission)