Tapping & Tubing

Sugarmakers invent gadget for easy droplines

Pair say it's priced to be practical for the normal syrup producer

By CALEB SCHROCK & JEREMY SWARTZENTRUBER | DECEMBER 2016

OAKLAND, Md. — We have done tubing installations and made droplines so we know how time consuming, strenuous and monotonous making drop-lines can be.

We knew there had to be better way so we started to design.

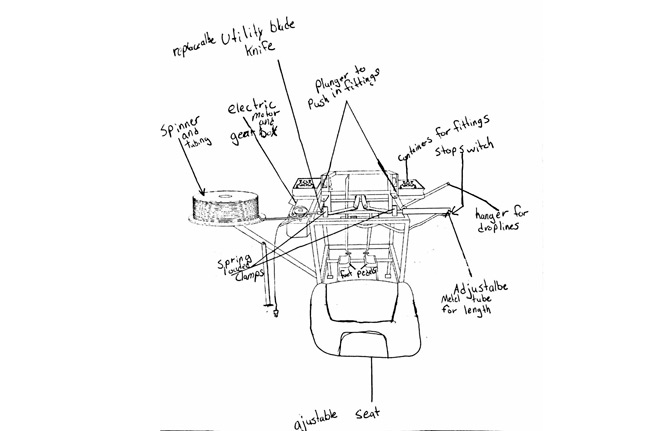

Our drop-line machine starts with a spinner which holds the roll of tubing. An electric motor/gearbox drives the tubing through the machine.

An electric switch with adjustment (for desired drop-line length) turns the motor off.

Meanwhile, you can be putting a fitting in each end of your drop-line at the same time, using the foot pedal. This foot pedal also operates the cutting device that cuts your drop-line to the desired length.

The clamping devices are operated with the other foot pedal which are spring loaded, which you push to open the clamps. Foot pedals are used to free hands and much less strenuous than conventional drop-line making tools.

There are two containers built into the machine — one bag (100 fittings) for ease of use.

This machine is excellent for people installing tubing, but priced so that it is very practical for the normal syrup producer.

We have a video clip of this machine we can send via e-mail. Request to gkswartz@yahoo.com.

We are also looking for dealers for this machine. Please call 301-616-9063.