Headlines

Syrup producer making hand sanitizer in response to crisis

Waiting on FDA approval for a maple-based hand sanitizer

By PETER GREGG | MAY 7, 2020

JEFFERSON, Ohio—Hand sanitizer could be the latest value-added crop from maple.

One Ohio producer is waiting for FDA approval to start distilling commercial grade syrup into ethanol as part of a recipe for a maple-based hand sanitizer.

“The demand for hand sanitizers is ridiculous,” said Nathan Bissell of 4,000-tap Bissell Maple Farms in Jefferson, Ohio.

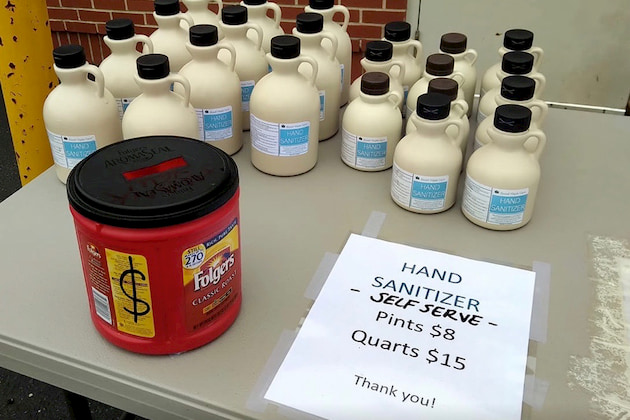

Meanwhile, Bissell has converted his idled syrup packing line into a hand sanitizer packing line, responding to the COVID-19 crisis and the high demand for virus killing product.

He has procured multiple 250 gallon totes of pre-made sanitizer from chemical suppliers and has put his employees to work packaging it into syrup jugs and selling and donating to locals.

“We’re helping solve a national crisis,” Bissell told The Maple News. “I have people that are really good at putting things in jugs.”

Bissell has donated the product to local hospitals and first responders.

He has also contracted with national businesses to pack the sanitizer in containers.

“National companies found out I had a bottling line,” he said. “I packed a semi-tractor trailer load today.”

The farm had lost at least 60 percent of its maple packing business overnight due to the Coronavirus shutdowns, he said. Most of his syrup went to the food service industry, which serves restaurants, most of which are closed across the nation.

“I had all that capacity,” he said. “This opportunity came.”

He said the pop-up sanitizer business is not for everyone.

Bissell has a chemical sales background and his facility is an old General Electric plant that was designed and built for chemical manufacturing.

“You need to know how to handle flammable liquid,” he said. “My facility is meant to handle this.”

He continues to wait for the FDA approval so he can distill maple syrup into an ethanol, the main ingredient in sanitizer, and make the product from scratch.

He has partnered with Kevin Milligan of Milligan’s Maple in Columbus, Ohio in the distilling project, he said.