Cornell Corner

Tap hole sanitation research in the ’17 season

Test results show several important outcomes

By STEPHEN CHILDS AND AARON WIGHTMAN, CORNELL MAPLE PROGRAM | FEB. 28, 2018

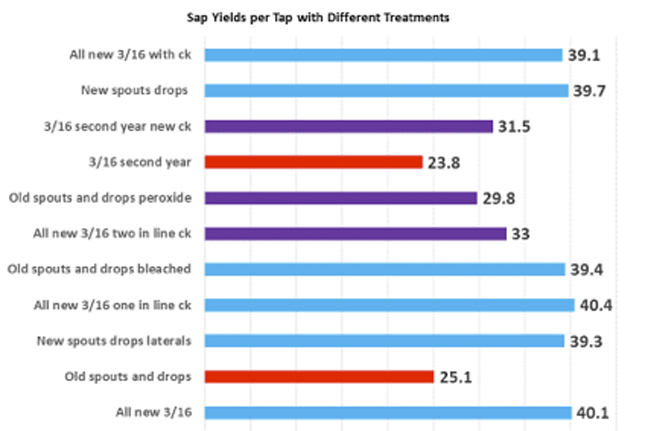

In 2017, 11 replicated maple tubing research plots were established at the Arnot Forest to provide information useful in identifying which methods of reducing microbial contamination of the tap hole are most effective and result in increased sap production. The plots are as follows:

1. All new 3/16

2. Old spouts and drops

3. All new spouts drops and lateral lines 5/16

4. All new 3/16 with one inline ck valve at the vacuum end

5. Bleach on spout and drop 30 min

6. All new 3/16 with ck in the middle and vacuum end

7. Peroxide drop and spout

8. 3/16 2nd year nothing changed

9. 3/16 2nd year with new check valve spout

10. 3/16 all new with ck valve spouts

11. Fall tap 3/16 all new

Sap production data is collected daily when sap is running throughout the sap season.

All the treatments were on vacuum mainlines that were operated between 22 and 24” of Hg but when temperatures would fall below freezing all the lines would drop to 0 vacuum due to freezing sap in the mainlines.

Test results show several important outcomes. First is that the poorest yielding system was the second year of using 3/16” tubing.

An earlier study showed that when trees drop below freezing temperatures, sap will be pulled back into the tap hole due to vacuum pressures developing in the tree and with 3/16” tubing the sap can be pulled back as much as 12 feet allowing significant microbe contamination to get into the tap hole and block future yield. It is important to note here that in this set of tests there was no significant elevation increase from the mainline to the end of the 3/16” lateral so the lines were not developing significant natural vacuum due to sap weight in the lines. Earlier tests with 3/16” lateral lines with 30 to 40 feet of elevation drop developed 15 to 26” of Hg at the spout which did not show any vacuum reduction during the whole season making it unlikely that sap was being pulled back into the taphole by the natural vacuum in the tree during periods of freezing.

Methods of stopping or sanitizing this contaminated sap before it can contaminate the tap hole will be a significant part of future tests with 3/16” tubing where there is no elevation induced natural vacuum advantage. The second poorest yield was with old spouts and drops in 5/16” tubing. This is typically true with new spouts and drops yielding 58% or 14.8 more gallons of sap per tap. Sanitizing spouts and drops with bleach with a contact time of 30 minutes was essentially the same yield as new spouts and drops.

New 3/16” tubing with or without check valves was essentially the same as new 5/16” tubing and spouts with the exception of where a diaphragm style check value was inserted into the tubing between every other spout in the lateral line. The diaphragm check valves seem to hinder sap flow when there was more than one. Once again sanitizing with peroxide was less successful than treating with bleach.

Field Observations for 3/16” Tubing

The Cornell Maple Program used 3/16” tubing extensively in a 2200 tap sugarbush expansion at the Arnot Forest in the summer of 2016. It was used most frequently in three applications: 1) long lateral line runs to access trees located far from and uphill from the main line, 2) areas with steep inclines, 3) to access trees located downhill from the main line. Basic performance metrics and observations were made to evaluate the functionality of 3/16’ tubing both generally and in these specific applications.

The longest lateral lines installed in the Arnot measure approximately 1200’ and is located on a steep (20 to 30%) slope with a northeast aspect. Additional lines of slightly shorter length were installed on the same hillside. During the season, vacuum measurements were taken at the top of each line. Initial measurements indicate a modest gain of several inches of vacuum. These measurements also confirmed that any amount of damage to the line completely eliminated the vacuum and reduced sap production in the line.

Out of necessity, several 3/16” laterals were installed to reach trees located below downhill from the main line. One of these lines sloped gently upward, gaining 20 feet in elevation to access the main. In several other locations, the lateral was spiraled around a tree to reach main lines elevated as high as 14 feet. In both instances, the sap was able to flow upward under vacuum according to observations throughout the season.

Vacuum levels at the tap in these instances was reduced from the vacuum in the mainline by about 1” for each foot the sap was lifted. In one example the vacuum in the mainline was 20” Hg and the sap was being lifted 14 feet in the 3/16” lateral line and vacuum at the tap was 6” of Hg. This area was surrounded by roads so the sap needed to be lifted up and over truck height.

Significant pull back was observed in 3/16” laterals, in particular those that were pulling sap uphill to the mainline and where lines had lost their integrity due to rodent damage or where lines pull apart. Pull back occurs when trees develop negative pressure during periods of freezing temperatures. When this occurs, sap is pulled through the lateral line back into the tree.

In the process, bacteria yeast and molds developing in the lines are pulled into the taphole, thereby increasing the rate of taphole closure. Past studies have found as much as 12 feet of pull back in 3/16” lines on a single tap. In 2017, much greater pull back was observed, including 42 feet of pull back on a long 3/16” lateral with significant slope up to the mainline. This reinforces the need to further test and develop means of maintaining sanitary tapholes in 3/16” lines including check valves, silver spouts and 5/16” drop lines on 3/16” laterals.