UVM Proctor Page

The Goldilocks Touch

Overdriving spouts reduces sap yield

By T.D. PERKINS, W. T. BOSLEY AND A.K. VAN DEN BERG | NOVEMBER 6, 2019

UNDERHILL CENTER, Vt.—One of the more common questions producers have when about tapping maple trees is “how deep should spouts be driven in to the taphole?”

Unfortunately, there is not a simple answer, since different spouts have different dimensions, variable degrees of taper and steps and are made of different materials with dissimilar degrees of “stickiness.”

Regardless, the importance of driving spouts in to the proper depth is readily apparent: if spouts are driven too shallow there is a risk that spouts can leak vacuum or heave easily during freezes, but if driven too deeply, small cracks may form which cause liquid and vacuum leaks or alternatively, the reduced amount of exposed wood surface area inside the taphole caused by driving spouts in too deeply may reduce sap collection.

Most frequently, producers drive in spouts by sound – a change to a “deader” sound indicating proper depth. However some producers feel that seating spouts more deeply than this lowers the chance that spouts will heave and cause leaks and a loss of vacuum, therefore reasoning that deeper spout seating reduces maintenance during the season.

Dr. Mike Rechlin of Future Generations University in West Virginia conducted a pilot study looking at spout placement depth on yield in response to unusually low yields of sap experienced by a producer.

He found that overdriving spouts resulted in a significant loss of sap collected.

Because the problem was only identified near the end of the season, the study was of a very limited sample size and was conducted over just a few days.

Nevertheless, this work demonstrated the potential that overdriving of spouts might significantly impact yield and might therefore an important factor to avoid, so we sought to explore the relationships further.

During the 2019 season, we set up 9 plots, each consisting of a single 3/16” lateral line running to 3 sugar maple trees. All the plots utilized natural vacuum developed in the 3/16” line, with 150 gallon poly collection tanks located about 30’ in elevation below the first tap on the line.

Trees averaged 11.3” in diameter, and each treatment was matched to have trees of comparable basal area, health, and slope position.

Trees were all tapped on the same day in February 2019 by one person prior to the commencement of any notable sap flow. All tapholes were drilled to 1.5” depth and 5/16” white CDL Maxflow spouts were used.

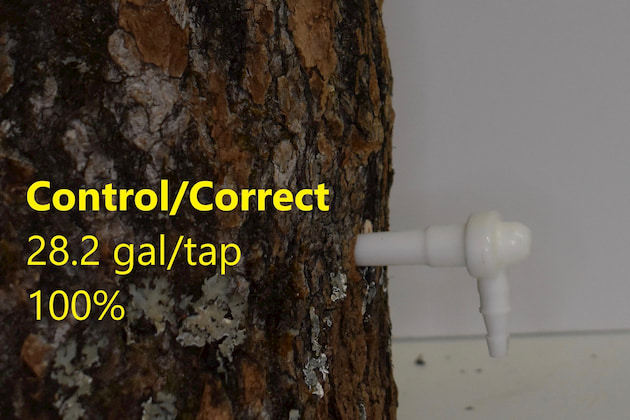

Three of the treatment plots had spouts driven to the proper depth (Control), as indicated by a change in sound (See photo).

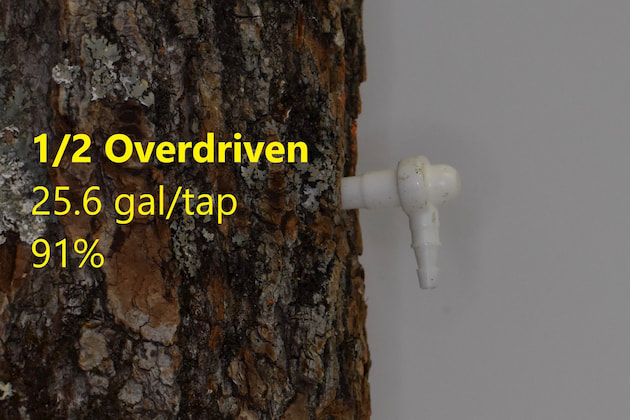

Spouts in another set of three plots were driven an additional 0.625” deeper than normal (1/2-Overdriven), and spouts in the remaining three plots were driven an additional 0.625” beyond that (Fully Overdriven).

Sap was collected over the entire season after which depth of the sap in the tank was measured and converted to yield (gal of sap/tap). Sugar content was measured with a calibrated hand-held Misco refractometer.

Average sap yield per treatment is also shown in Figure 1. Sap yield was highest with proper seating (Control), was slightly reduced when spouts were 1/2 Overdriven, and was greatly reduced when they were Fully Overdriven.

It should be noted that this particular spout design has a “step”, which prevents extreme overdriving of spouts – some spout designs do not incorporate a “step” and thus could be overdriven even further, likely resulting in further reductions in sap yield.

Clearly, seating spouts to the correct insertion depth produced the optimal result (highest sap yield).

Overdriving of spouts produced a non-linear reduction of sap with increasing depth, probably as a result of restricting sap flow from some of the wood vessels in the taphole, but possibly also due to leaks from cracks caused by overdriving spouts (although no signs of leaks were observed).

Whereas a little overdriving produced only a modest loss of sap yield (9.3%), continued overdriving resulted in a loss of over 40% of potential sap, representing a serious loss of revenue. No differences were observed in sap sugar content.

These results provide clear and strong evidence that maple producers should learn proper tapping technique and pay close attention when tapping to employ the right methods in order to ensure the highest sap yields possible. Seating spouts too deeply is clearly detrimental, however not seating spouts deeply enough also creates problems.

Proper depth of spout seating is truly a “Goldilocks” proposition. In order to achieve optimal yields producers must seat spouts in the taphole just right -- not too hard, but not too soft.

Maple equipment manufacturers may wish to add some type of guide or mark on spouts indicating the range of proper seating depth, although this would have to be moderated to some degree by producers to account for variations in bark thickness.

Acknowledgements. Thanks to Brendan Haynes (UVM PMRC) for field assistance in setting up this study as well as to Mark Isselhardt for discussions on the topic. Dr. Mike Rechlin (WV) provided the initial suggestion and conducted a preliminary study suggesting that spout insertion depth was important. This project was funded by the Agricultural Experiment Station of the College of Agriculture & Life Sciences at the University of Vermont.