Food Safety & Gov't Regulations

Why does my syrup taste sick? Tips for avoiding off flavor this season

Vermont experts weigh in on beating the buddy and other off flavor problems

By PETER GREGG | MARCH 11, 2021

MORRISVILLE, Vt.—Flavor is weird.

“Flavor is a personal experience, ” said Mark Isselhardt, the UVM Extension Maple Specialist who led an online seminar on identifying flavor in syrup called “Why does my syrup taste sick?”

"It may be influenced by what your family grew up favoring," he said.

Isselhardt was joined by former Vermont agency of agriculture inspector Henry Marckres, a legend in the state and a leading expert on syrup quality.

Both encouraged sugarmakers this season to pay close attention to taste and quality and identify flavors that would be different than normal.

“If it doesn’t taste quite right, bring it home and have someone else taste it,” Marckres said.

“At some point in the season someone in the sugarhouse will say ‘it doesn’t taste that bad,’” he said. “That should be the time to be critical about what the flavor is.”

Since the sugarmaker doing the boiling might be saturated in syrup and syrup smells, that person might not be the best one conduct the taste test.

“Some people can pick up flavor better than others,” he said.

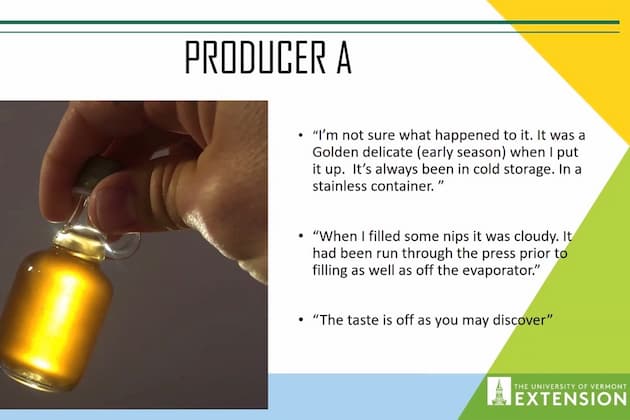

During the seminar Isselhardt and Marckres tasted samples sent in anoymomously by sugarmakers.

First thing to do when sampling syrup is to smell it.

“Your nose can save your stomach from yourself,” Marckres said.

Then roll it in your mouth. Is something off?

“Is there a different mouth feel?” he said.

One of the more common off-flavors is metabolism.

“That’s a hard one to pick up in the sugarhouse,” Marckres said.

The University of Vermont offers off-flavor testing kits to help the sugarmaker identify metabolized syrup and take it off sale.

One of the biggest culprits in creating bad tasting syrup is the filtering process.

“Use the best filters you can,” Marckres said.

If the sugarmaker is using a gravity filter, wash filters between use.

“Don’t use a household washing machine,” he said.

“Once you wash and rinse they have to dry very well,” he said. “If they don’t dry well you can get a musty moldy flavor in your syrup.”

Other problems can occur.

Make sure not to store Diatomaceous earth in a garbage can. Moisture can get in and create mold.

Also sometimes a problem are barrels for syrup storage.

Isselhardt said sugarmakers should make sure all water is removed from the barrels after steam cleaning.

“Get water out as soon as you can when you get them back from the packer,” he said.

“People filled barrels that were steam cleaned and then kept all summer and not drained out before the next season,” Isselhardt said. “If you don’t inspect each barrel you can impart a bad flavor.”

Then there’s the buddy.

Buddy syrup is the worst offender in off-flavor problems.

It will come at the end of the season.

“Buddy can be mild and it can be severe and everything in between,” Isselhardt said.

Often it will have a chocolatey flavor to it.

“It might taste like a Tootsie Roll,” Marckres said.

Once it’s discovered, stop making it and make sure it never hits the store shelf.

It’s not worth trying to blend it out either.

“I’ve never had much luck with blending,” Marckres said. “If you add good syrup to it you just end up with more buddy syrup.”

Other tips for avoiding bad tasting syrup is making sure density is correct. Low density will lead to mold.

Make sure to test syrup in the hydrometer cup, not in the draw off pail.

“Syrup cools rapidly,” Marckres said. “When you expose syrup to air and the pail the temperature drops. It will probably be 180 degrees in the pail.”

Meanwhile, syrup grading is the next step to making sure the product is the best for the consumer.

“Use a grading kit in good light,” Marckres said.

In the conventional gradating kit sugarmakers should compare the syrup to the test vials going by which one is equal or lighter than the tester.

“You have to know how to use your kit,” he said. “It goes by equal or light, not the one it’s closest to.”